Success in the manufacturing industry depends on how everything works, so creating standard work by clearly defining and structuring what is done is crucial.

Process, procedure, and work instructions are created to standardize and control work.

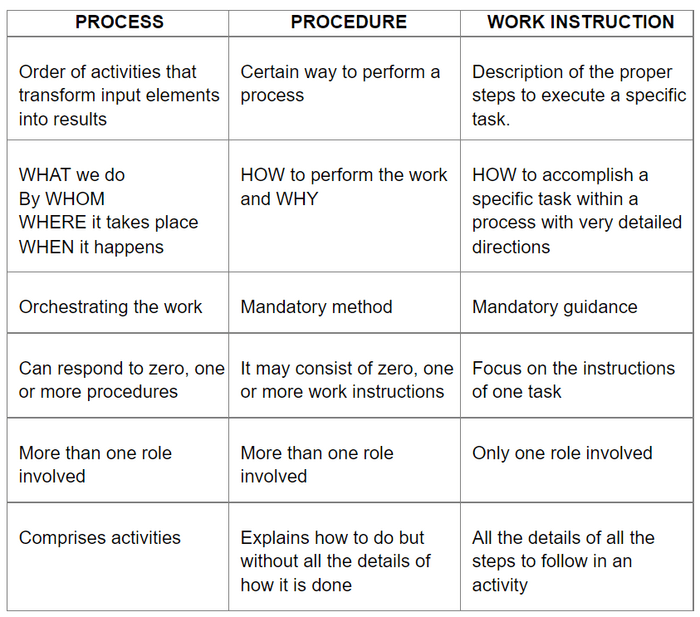

And there are distinctive characteristics between these three types of documentation, which often cause confusion in their application. So let’s focus on each of these types of documentation by comparing and contrasting them.

What Are Work Processes?

The work process is a concept that describes standard procedures or a set of steps aimed at achieving a particular goal. According to The ISO 9001 Standard, this manufacturing process is “a set of related or interacting activities, which transform inputs into outputs.”

In general, work processes show the big picture and involve people from different departments and roles. As a rule, a work process covers a much longer period than procedures or work instructions. This is because it requires multiple procedures and many work instructions to detail every task performed by many actors to accomplish a particular goal.

Work Process Structure

Here’s a work process document structure to help you make your own:

- Process name.

- Purpose – Describe why you are creating your process documentation.

- Scope – Explain what activities the process includes and doesn’t include.

- Process boundaries and measurements – Outline the timing for your project and what measurement you plan to use to determine completion.

- Process inputs – Describe the resources needed to perform your project.

- Process outputs – Share the end result or product generated from the project.

- Procedures:

- Step 1;

- Step 2;

- Step 3;

- etc.

- Potential risks or exceptions – Summarize any potential risks or exceptions your company may have during the project.

- Related resources – Include links to relevant materials that help support the process.

What Is a Working Procedure?

You should not confuse the procedure with the process. The procedure is the following step towards a designated goal. It is a more detailed description of the steps to be taken by the operator reading it. It is usually referred to as a Standard Operating Procedure (SOP) or a Guidebook.

The ISO 9001: 2015 determines a procedure as a “specified way to carry out an activity or a process”.

With a process at hand that should be performed in a certain way, where you specify how it happens, you have a procedure. Remember that not all processes need to have a procedure, and, as mentioned above, the same process may have associated one or several procedures.

A procedure is determined by the need to itemize the specific way of doing the actions by legal issues, regulatory compliance, or company policies. The procedures are the activities with several operations connected and different people or departments of the company involved (for example, Purchasing Procedure, Evaluation Procedure, Automation Procedure, and the like). Well-prepared procedures help you improve the quality of work within your organization, reduce the number of errors, and help new people perform complex tasks quickly and effectively.

Work Procedure Structure

A work procedure structure includes the following items:

- Intro to a work procedure – Note the audience, what the procedure is designed to do, who will do it, and why it’s important.

- List of resources – Include tools, passwords, keycodes, technology, physical items (pen, paper, etc.), and anything else that might be required.

- Overview – Make sure that readers can understand everything they need to know in order to complete the procedure at a glance, rather than making them work to get the information they need.

- Related checklists – Check with the team that the steps you’ve documented cover the procedure in its current state.

Definition of a Work Instruction

Work instructions are mandatory documents that clearly and precisely describe the correct way to perform certain tasks that may cause inconvenience or damage if not done in an established manner. The purpose of work instructions is to describe, dictate or stipulate the steps that must be followed to correctly perform any specific activity or work.

A work instruction often repeats some elements of a procedure to help describe where it fits into the process, such as:

- Purpose

- Definitions

- Responsibility

- Requirements

- Tools and information

But essentially, a work instruction contains the step-by-step detail that is not advantageous to put into a procedure because it requires such a limited scope.

Work Instructions Structure

A work instruction structure is handy in providing both detailed and specific information to execute and perform any activity smoothly. A common work instruction comprises:

- less than ten separate actions;

- a task to be performed by one person from start to finish;

- a relatively short time period to complete;

- visual aids to show the work rather than words that describe the work.

Here’s a template of a basic work instruction format:

- Work instruction No.

- Purpose.

- Scope: the areas and processes applied.

- Records: specific records to be maintained and how to do it.

- Associated documents: other relevant documents.

- Definitions: the tasks and phrases explanation.

- Responsibility: people responsible for maintaining the instructions.

- Tools: devices needed to perform the task.

- Safety requirements: safety precautions to comply with.

- Instructions: in successive steps.

- Appendices: flowcharts.

- Supervisor name.

- Signature.

Think of your work instruction as an educational tool. Put yourself in the reader’s shoes and think about what could help them easily use the document.

Difference Between SOP and Work Instructions

Different organizations have developed their own internal definition and application of these terms. But, generally, work instructions describe the tasks carried out by one operator for a certain job. They answer the question of HOW to do a particular action. While standard operating procedures (SOPs) answer the questions of WHO, WHAT, and WHEN. In other words, work instructions detail how to execute SOPs. It is crucial to choose the correct document for specific tasks. Let’s take a manufacturing company, for example, a shop floor operator receiving a plant-level process, which lacks task-specific detail, will struggle to perform their job correctly.

If you need a hint on how to write SOPs, read our article How to Write Standard Operating Procedures.

Differences Between Process, Procedure, and Work Instruction

What is the difference between a process, a procedure, and a work instruction? If processes and procedures define the way of working, then work instructions are the critical link between standard work and the human element of manufacturing.

Conclusion

Any document created should serve a certain purpose otherwise it is nothing more than a waste of precious space. Processes, procedures, or work instructions are only effective when employees use them to complete their tasks seamlessly and communicate effectively, therefore, improving business processes.

Good luck with your technical writing!

ClickHelp Team

Author, host and deliver documentation across platforms and devices